Cell Line Development Products

Cell line development is the process by which the cellular machinery is co-opted to manufacture therapeutic biologics or other proteins of interest. Discover products for this pivotal process below.

Products for Cell Line Development

Optima Ultracentrifuges

Our premier line of ultracentrifuges for high quality separations

ValitaTiter Assays

Rapid, high-throughput IgG quantification in crude cell culture samples

CytoFLEX SRT

Simplify your population sorting with the CytoFLEX SRT Cell Sorter

Biomek i-Series

Automate every step of the complex Cell Line Development workflow - from transfection to enrichment to limiting dilution to culture/feeding to assaying to hit-picking and expansion.

Echo 525

Acoustic liquid handling for precise and accurate low volume transfers enabling assay miniaturization

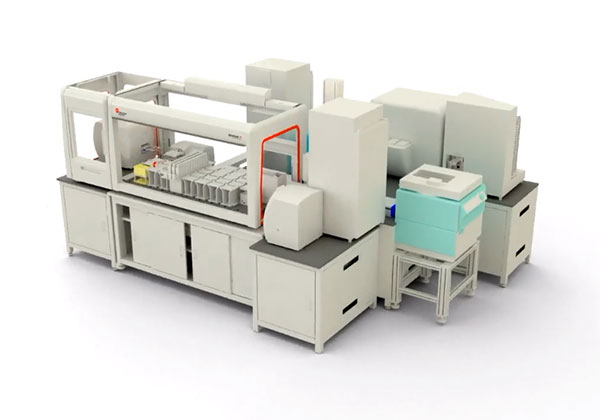

Access Solutions Systems

Discover a comprehensive suite of high-throughput automation platforms that are easily integrated to meet each critical step of your cell line development workflow.

Avanti JXN Series

High performance centrifugation for cell culture harvest and purification optimization

MoFlo Astrios

Provides an automated, high throughput single cell depositing system. This process is mandatory for master cell bank generation.

Vi-CELL MetaFLEX

Use the Vi-CELL MetaFLEX for fast bioreactor media analysis

Vi-CELL BLU

Used at multiple steps along cell line development. Eliminate human error and user bias when counting cells and determining viability.

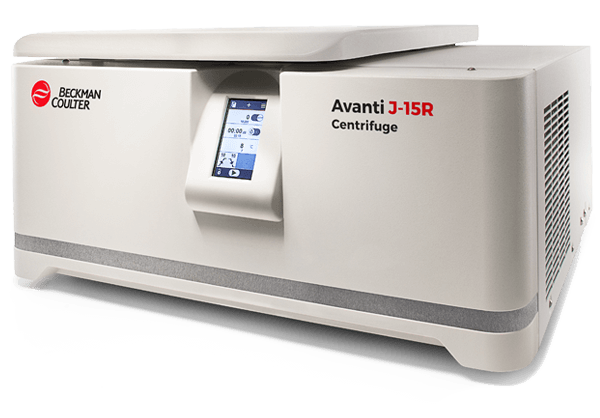

Avanti J-15R

Separate cells from culture media for antibody titer assays, quantification. Pellet cells for media exchanges.